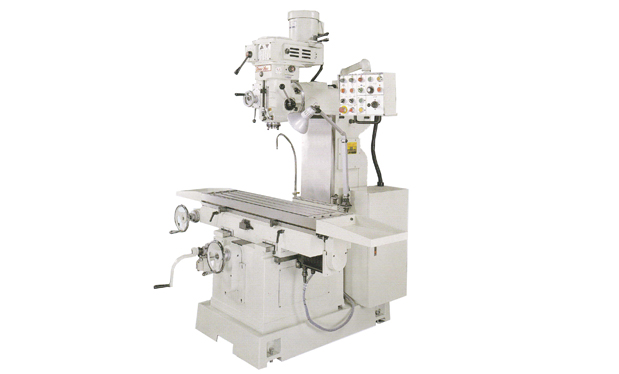

•All casting is finished through annealing stress with M casting iron; the slides for X, Y, Z- axle are handled by heating and grinding; the sliding for X, Y- axle is light and clever without abrasion because of pasting anti-abrasion pieces. We use C5 level for X, Y-axle, pre-pressed nut of ball screws, which is to press smoothly and position well due to small gap. Using the timing oil-filling on X, Y, Z axle and nut to ensure the precision for each section.

•The table adopts dovetail type, double-sided pins, saddle width 1250mm, and the contact surface with the table is increased.

•The base is bed type, which has higher processing stability compared with the knee type, and the column is widened to enhance rigidity and toughness.

•Using servo motor on X.Y-axle for DY-2500V. Z-axle use motor of reducing speed to reach a rapid up and down motion.

•Using a cannon head with strong structure of vertical milling head. The inside grinding gear is to fill oil by enforcement, 20-stage transmission. (it’s optional to select frequency non-stage transmission.) To shorten the working time and upgrade the enterprise competition because the core of the axle is able to have a boring automatically.